A solid understanding of GAAP and taxation are the building blocks or foundation used by every Controller. To become a strategic, high-performing Controller, the tools in a Controller’s toolbox must expand to be inclusive of tools with an operational focus.

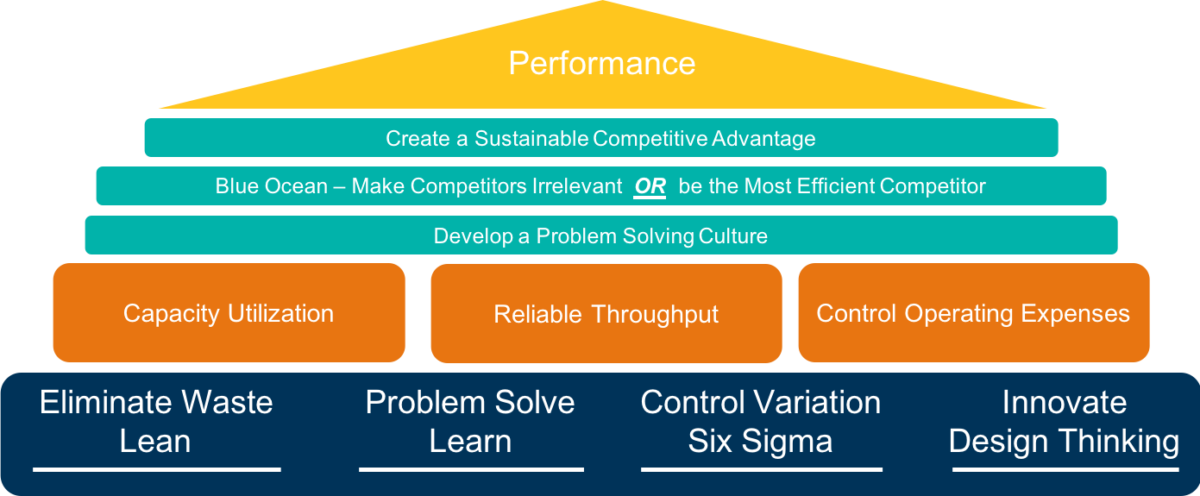

In every organization, financial performance is managed in relation to capacity utilization, reliable throughput, and controlled spend. And in each of these business processes, inputs drive outputs. Therefore, a strategic Controller’s toolbox may include process improvement and innovation, Lean Manufacturing, Six Sigma, Learning Loops, Fishbone Diagrams, and Design Thinking.

In this post, learn how to leverage process improvement and innovation, Lean Manufacturing, and Learning Loops as part of your toolbox. Part two of this blog series will cover Six Sigma, Fishbone Diagrams, and Design Thinking.

Process Improvement and Innovation

A strategic Controller is the leader in the organization who connects financial matters with the needs of the business enabling it to operate at optimal levels. To serve this role, Controllers must continually seek ways to innovate and improve processes.

To create a high-performing organization, Controllers should make sure their goals are focused and in alignment with the goals of the organization. A strategic Controller may set the following strategies:

- Create sustainable competitive advantages

- Manage three factors driving profitability

- Develop programs to maintain or create a culture of continuous improvement

When a Controller ensures the financial goals are in alignment with the business goals, they are able to articulate what is or isn’t moving the needle for the organization and in turn can help to shape, focus, and inform C-suite discussions on organizational performance.

The diagram below demonstrates how a Controller can contribute as a strategic leader in their organization. The base layer – eliminate waste, learning, control variation, and innovate – represents tactics Controllers can rely on to create competitive advantages and profits for the organization.

Lean Manufacturing

Lean Manufacturing is about effectively engaging people, equipment, and facilities. Lean works by focusing on creating flow in the value stream required to develop a product for a customer. Any disruption in flow represents an opportunity to improve processes in the business.

The more effective a process is across resources, the greater the contribution it can provide for any given level of investment and spend. And increasing contribution without increasing spend leads to greater profitability for the organization.

Challenge

Try this exercise: Review your trial balance over an eighteen-month period and calculate your total spend on a month-by-month basis.

If you are a manufacturing company, subtract the cost of raw materials from this number. This should represent your total spend on labor, overhead, and Sales, General, and Administrative (SG&A) costs. Plot the monthly results. Is the monthly variation in total spend relatively small (this example assumes there has been no significant growth during the period or “special cause” variation)?

Now ask yourself: How can I drive more contribution across this spending level?

Learning Loops

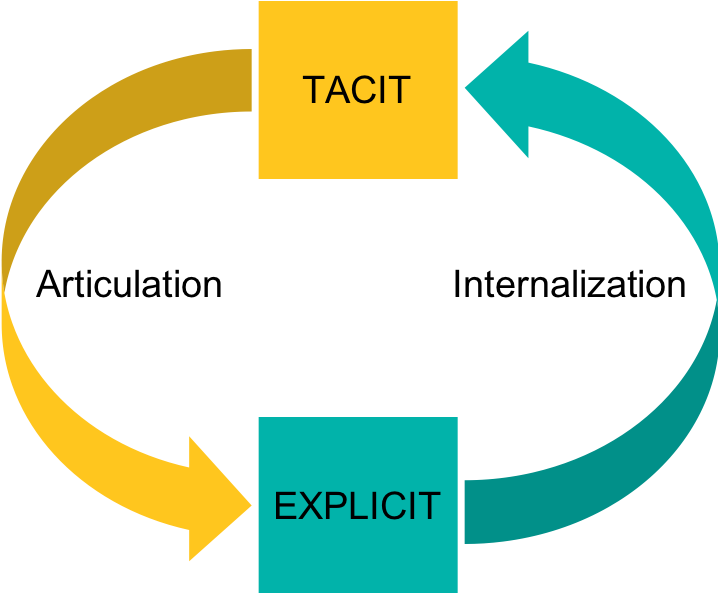

It is a known fact that organizations that learn, adapt, and innovate faster than their competition enjoy a significant competitive advantage in the marketplace. The Controller who understands and knows how to create an environment that nurtures this significantly contributes to the success of its organization.

The graphic illustrates a basic approach. Start with tacit knowledge – something you know how to do. When you can articulate it, by explaining how it’s done, you create explicit knowledge. When explicit knowledge is internalized and applied to a unique problem and fills a need, you have achieved learning and innovation.

What’s next?

The first step toward becoming a strategic Controller is ensuring you have the basics in place – accurate, timely, and compliant reporting of your organizations financials. With the foundation firmly in place, it is time to begin taking steps that boost the performance of your organization. Principles such as Lean Manufacturing, Six Sigma, Design Thinking, and beyond will help you to become a strategic, high-performance organization.

How can Resultant help?

Resultant has helped countless organizations assess the state of their current financials and develop a plan that details which principles to apply as well as how and when to apply them – all to help Controllers chart their course to growing into strategic organizational leaders.

It isn’t possible to successfully transition to a high-performing organization all at once. We recommend starting with a small initiative. If you need assistance assessing your current state, Resultant’s Financial Services team is ready to help. Contact us today to learn more about how we can help your organization begin its path toward becoming a strategic, high-performing organization.

Share:

About the Author

Steve Combs

Manager, Financial Systems and Services @ Resultant