One of the most daunting threats to our national defense is the vulnerabilities within complex global supply chains of microelectronic components. These parts are integral to strategic weapon systems and warfighting assets, and hackers have exposed weaknesses that earlier supply chain analytics couldn’t catch. In 2015, for instance, a compromised supply chain enabled a hardware attack that allowed Chinese spies to reach several large U.S. companies, including Amazon and Apple.

When supply chains for military warships are compromised, the consequences become dire. A new, product-focused approach to evaluating global supply chains helps secure our national defense.

At the November 5 Innovation Digi conference, Resultant Director of Data and Development Services Colin Stauffer walked attendees through our solution for NSWC Crane Division, the world’s third largest naval installation.

Toward a more robust supply chain analysis

Crane facilitates advanced technical capabilities for defense systems and is the Department of Defense’s largest multi-service facility for electronic warfare. Which is where Resultant comes in.

With so much at stake, Crane has led the nation in supply chain analysis, but its process still was manual, time-consuming, and not as reliable as DoD would hope. At the time we connected with Crane, Stauffer said, more than 200 requests for supply chain risk reports were waiting, each of which would require about 80 person-hours to complete.

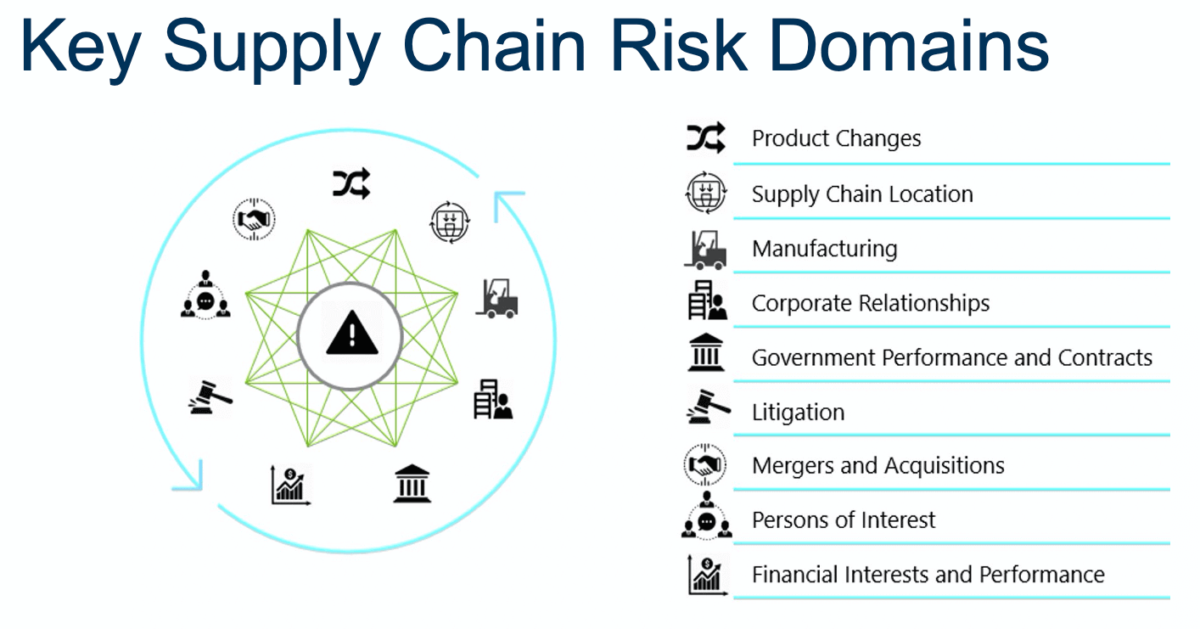

Solutions for supply chain analysis focused on corporate risk rather than devise-intrinsic risk: “In the traditional process, supply chains are built out of relationship analysis, leveraging network traffic, commercial datasets, press releases, and past invoicing to determine which companies do business together,” Stauffer said. “Because this analysis is not device specific, the confidence of an accurate supply chain map rapidly diminishes at lower supply chain tiers.”

The award-winning Automated Microelectronics Analysis and Reporting Optimization (AMARO) takes a different approach.

Analyzing risk at the part level

Using AMARO’s advanced analytics, system designers get the information they need to address part-specific risks when making tradeoff decisions during system design or making end-of-life determinations. Analysts and intelligence organizations can intervene or remediate macro risks, and defense agencies can identify trends across the semiconductor industry to inform policy and investment decisions.

Stauffer showed a demo of the AMARO analytics process and explained its supply chain and analytical capabilities, including:

- Examining key indicators of counterfeit risk, such as sole-source dependency and global availability of authorized in-stock versus independent or brokered inventory

- Monitoring the financial health of not only the component manufacturer but the financial health of critical nodes in its supply chain to assess resiliency

- Identifying a company’s key personnel and their career relationships and tracking the movement of key personnel from company to company to identify trends

- Quickly and intuitively tracking millions of relationships across the complex global semiconductor supply chain by using a complex nodal analysis module built on top of a graph database

Impacting security and efficiency

“By implementing the AMARO solution,” Stauffer said, “the time it takes to turn around a report request has been reduced by over 60%. This allows NSWC Crane to focus its time on more value-add risk assessment and remediation activities for OSD.”

AMARO also puts supply chain risk data into the hands of program managers, designers, analysts and policy makers across the DoD in a way that previously wasn’t possible. Programs have access to the most robust and accurate supply chain data, allowing for data-driven decision making and reducing our national exposure to microelectronic part supply chain risks.

To read more about the AMARO solution for NSWC Crane, download our brochure and for more information on how AMARO can easily be tailored for other sectors and industries, please get in touch.